PA66美国杜邦101L BKB009阻燃级耐高温耐磨热稳定性尼龙66耐老化PA66聚酰胺

-

DuPont Performance Polymers Zytel® 101L BKB009 Nylon 66 PA66

Polymer,Thermoplastic,Nylon,Nylon 66

DuPont Performance Polymers

产品说明:

Zytel® 101L BKB009 is a lubricated polyamide 66 resin for injection molding.

Information provided by DuPont Performance Polymers

DuPont Performance Polymers Zytel® 101L BKB009 Nylon 66 (Unverified ) 物性表 工程塑料

物理性能

额定值 (公制)

额定值 (英制)

测试方法

密度

1.14 g/cc

0.0412 lb/in³

DAM; ISO 1183

机械性能

额定值 (公制)

额定值 (英制)

测试方法

抗张强度(屈服)

88.0 MPa

@Temperature 23.0 °C

12800 psi

@Temperature 73.4 °F

DAM; ISO 527

伸长率 (断裂)

16 %

@Temperature 23.0 °C

16 %

@Temperature 73.4 °F

DAM; nominal; ISO 527

屈服伸长率

4.6 %

@Temperature 23.0 °C

4.6 %

@Temperature 73.4 °F

DAM; ISO 527

拉伸模量

3.05 GPa

@Temperature 23.0 °C

442 ksi

@Temperature 73.4 °F

DAM; ISO 527

弯曲模量

2.80 GPa

@Temperature 23.0 °C

406 ksi

@Temperature 73.4 °F

DAM; ISO 178

简支梁无缺口冲击强度

13.4 J/cm²

@Temperature -30.0 °C

63.8 ft-lb/in²

@Temperature -22.0 °F

DAM; ISO 179/1eU

20.3 J/cm²

@Temperature 23.0 °C

96.6 ft-lb/in²

@Temperature 73.4 °F

DAM; ISO 179/1eU

简支梁缺口冲击强度

0.370 J/cm²

@Temperature -30.0 °C

1.76 ft-lb/in²

@Temperature -22.0 °F

DAM; ISO 179/1eA

0.400 J/cm²

@Temperature 23.0 °C

1.90 ft-lb/in²

@Temperature 73.4 °F

DAM; ISO 179/1eA

电气性能

额定值 (公制)

额定值 (英制)

测试方法

相比耐漏电起痕指数(CTI)

>= 600 V

@Temperature 23.0 °C

>= 600 V

@Temperature 73.4 °F

DAM; UL 746A

热性能

额定值 (公制)

额定值 (英制)

测试方法

熔融温度

262 °C

504 °F

10°C/min; DAM; ISO 11357-1/-3

载荷下热变形温度(0.46 MPa)

200 °C

392 °F

DAM; ISO 75-1/-2

载荷下热变形温度(1.8 MPa)

70.0 °C

158 °F

DAM; ISO 75-1/-2

UL RTI

65.0 °C

@Thickness 0.400 mm

149 °F

@Thickness 0.0157 in

DAM; UL 746B

65.0 °C

@Thickness 6.00 mm

149 °F

@Thickness 0.236 in

DAM; UL 746B

130 °C

@Thickness 0.710 mm

266 °F

@Thickness 0.0280 in

DAM; UL 746B

UL RTI,机械冲击

65.0 °C

@Thickness 0.400 mm

149 °F

@Thickness 0.0157 in

DAM; UL 746B

65.0 °C

@Thickness 6.00 mm

149 °F

@Thickness 0.236 in

DAM; UL 746B

75.0 °C

@Thickness 0.710 mm

167 °F

@Thickness 0.0280 in

DAM; UL 746B

UL RTI,机械无冲击

65.0 °C

@Thickness 0.400 mm

149 °F

@Thickness 0.0157 in

DAM; UL 746B

65.0 °C

@Thickness 6.00 mm

149 °F

@Thickness 0.236 in

DAM; UL 746B

85.0 °C

@Thickness 0.710 mm

185 °F

@Thickness 0.0280 in

DAM; UL 746B

可燃性(UL94)

V-2

@Thickness 6.00 mm

V-2

@Thickness 0.236 in

DAM; IEC 60695-11-10

V-2

@Thickness 3.00 mm

V-2

@Thickness 0.118 in

DAM; IEC 60695-11-10

V-2

@Thickness 6.00 mm

V-2

@Thickness 0.236 in

DAM; IEC 60695-11-10

V-2

@Thickness 3.00 mm

V-2

@Thickness 0.118 in

DAM; IEC 60695-11-10

V-2

@Thickness 1.50 mm

V-2

@Thickness 0.0591 in

DAM; IEC 60695-11-10

V-2

@Thickness 0.710 mm

V-2

@Thickness 0.0280 in

DAM; IEC 60695-11-10

V-2

@Thickness 1.50 mm

V-2

@Thickness 0.0591 in

DAM; UL94

V-2

@Thickness 0.710 mm

V-2

@Thickness 0.0280 in

DAM; UL94

V-2

@Thickness 0.400 mm

V-2

@Thickness 0.0157 in

DAM; UL94

V-2

@Thickness 1.50 mm

V-2

@Thickness 0.0591 in

DAM; UL94

V-2

@Thickness 0.400 mm

V-2

@Thickness 0.0157 in

DAM; IEC 60695-11-10

V-2

@Thickness 1.50 mm

V-2

@Thickness 0.0591 in

DAM; IEC 60695-11-10

V-2

@Thickness 6.00 mm

V-2

@Thickness 0.236 in

DAM; UL94

V-2

@Thickness 6.00 mm

V-2

@Thickness 0.236 in

DAM; UL94

V-2

@Thickness 3.00 mm

V-2

@Thickness 0.118 in

DAM; UL94

V-2

@Thickness 3.00 mm

V-2

@Thickness 0.118 in

DAM; UL94

灼热丝易燃指数

725 °C

@Thickness 0.710 mm

1340 °F

@Thickness 0.0280 in

DAM; Ignition; IEC 60695-2-13

750 °C

@Thickness 1.50 mm

1380 °F

@Thickness 0.0591 in

DAM; Ignition; IEC 60695-2-13

800 °C

@Thickness 3.00 mm

1470 °F

@Thickness 0.118 in

DAM; Ignition; IEC 60695-2-13

960 °C

@Thickness 3.00 mm

1760 °F

@Thickness 0.118 in

DAM; IEC 60695-2-12

960 °C

@Thickness 0.710 mm

1760 °F

@Thickness 0.0280 in

DAM; IEC 60695-2-12

960 °C

@Thickness 1.50 mm

1760 °F

@Thickness 0.0591 in

DAM; IEC 60695-2-12

加工性能

额定值 (公制)

额定值 (英制)

测试方法

加工(熔体)温度

290 °C

554 °F

DAM; Optimum

280 - 300 °C

536 - 572 °F

DAM

模具温度

70.0 °C

158 °F

DAM; optimum

50.0 - 90.0 °C

122 - 194 °F

DAM

干燥温度

80.0 °C

176 °F

DAM

干燥时间

2.00 - 4.00 hour

2.00 - 4.00 hour

DAM

水分含量

<= 0.20 %

<= 0.20 %

DAM

材料描述

测试方法

形式

Pellets

DAM

Generic

Nylon 66

DAM

Material Status

Current

DAM

部件标识代码

>PA66<

ISO 11469; DAM

加工方法

Injection Molding

DAM

产品分类

Unreinforced Resins

DAM

树脂识别

PA66

ISO 1043; DAM

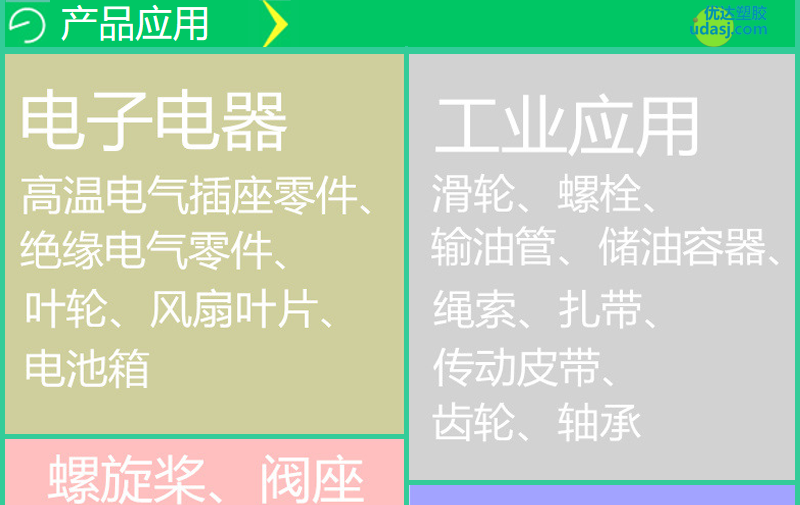

符合RoHS指令

Contact Manufacturer

DAM

ASTM D638

-